There have been many case studies demonstrating Six Sigma at large companies. However, small and medium-sized businesses adopting Six Sigma have received less attention. The question remains whether they can replicate the same level of success achieved by big businesses. The answer is yes! A North American Plumbing Products company leveraged DMAIC and Six Sigma to improve cycle time and increase sales.

Read more: Improving Cycle Time with Six SigmaThree mechanical engineering and academia professionals conducted a study and published it in the SAGE Journal in 2017. The study focused on a plumbing product manufacturing company. They employed the Six Sigma DMAIC process to decrease production defects in PVC pipes and fittings and improve sales with the goal of Improving Cycle Time with Six Sigma.

Pipes and plumbing play a crucial role in various sectors worldwide, serving as water, sewage, and chemical conduits. The following section shows the authors’ strategy for implementing DMAIC under the Six Sigma methodology.

Doing The Research: Improving Cycle Time with Six Sigma

The authors based the case study on a small-to-medium-sized enterprise (SME) in the United States that produces plumbing products. The project took place within the company’s business unit over one and a half years.

Before doing the research, they analyzed the process to improve the quality and productivity indicators. This allows them to establish a basis for using the Six Sigma methodology. Then, a project team was formed and instructed to use the DMAIC process. With this, the researchers use specific statistical analysis tools at each stage of the DMAIC cycle.

Improving Cycle Time with Six Sigma by DMAIC Phase

The authors understand that the Six Sigma infrastructure relies on creating teams to complete the projects. It contributes to achieving the company’s strategic goals. After determining the project’s focus and research, they employed and integrated the DMAIC cycle with quality tools. Some of the tools used during the research included the following:

- Voice of the customer (VoC)

- Quality function deployment (QFD)

- Benchmarking

- Multiple regression, and more.

The following shows how the DMAIC cycle was implemented:

Define Phase

The team created a project charter. It outlined members, the process to be improved, and project objectives to initiate the Six Sigma project.

Once the team creates the project charter, the Define phase can begin. This phase focuses on identifying the project’s objectives and understanding its value. It is important to understand the problem the project addresses, its desired outcome, and its economic impact. Additionally, it is important to understand the process related to the problem and how it affects customers.

To help with this understanding, the team can use the Voice of the Customer (VoC) tool. This tool helps identify customers’ expectations, needs, and perceptions about the company’s products and services. Then, the team benchmarked the company’s performance against its competitors. This helped them to understand better where the problems lie and how to address them.

A market research study was done. The study showed low customer satisfaction with the plumbing company’s order fulfillment cycle time (OFCT). As a result, the team focused on improving this process to reduce costs and increase customer satisfaction.

Measure Phase

The authors created a comprehensive data collection plan to better understand SMEs’ delivery cycle time. This plan includes information about execution, performance timing, sample size, and the operational definition of indicators. According to market research, SMEs had a 46% longer delivery cycle time than competitors.

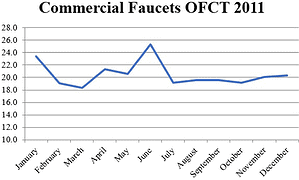

During this phase, the team used two main metrics, OFCT and inventory dollars. The team set a goal of keeping inventory cost neutral while reducing product delivery time to customers.

The team worked on finding areas where they could cut delivery time without notably increasing inventory costs. Data analysis showed areas needing improvement, leading to desired changes.

Analyze Phase

The project team did extensive data analysis to determine the primary reasons for the company’s slow turnaround. The team evaluated several factors, including:

- Sales plan accuracy

- Vendor delivery performance

- Safety stock fill

- Manufacturing schedule adherence

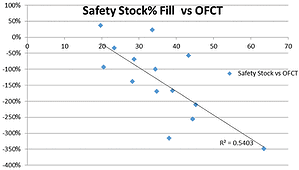

The goal was to identify the most impactful variables affecting the company’s overall performance. Using regression analysis, the team measured the impact of each independent variable on the dependent variable (OFCT). Safety stock fill and sales plan accuracy were the most prominent variables. The authors identified these factors as the root causes of the company’s slow turnaround and targeted them for improvement.

The team created a histogram and a Pareto diagram to focus their efforts further. They use these tools to analyze the company’s stock-keeping units (SKUs) and identify the most popular products. The team found that just 52 of the company’s 252 products accounted for 74% of its annual sales. With this information, the team prioritized efforts to maintain the stock of these popular items to improve overall performance.

Improve Phase

During this stage, the emphasis is on discovering a long-term resolution to the issue. It involves introducing a monthly assessment that centers on the need for the most sought-after items. Furthermore, these goods were labeled for tracking, allowing for dependable forecasting. This would enhance the company’s ability to maintain an inventory of popular items and address changes in demand effectively.

Control Phase

The project team documented new solutions for consistent plumbing product company progress. After careful assessment, the team identified two crucial actions that would be necessary to maintain the improvements achieved. The company needs to review the main pipes and plumbing products monthly. In addition, it needs to conduct an annual coding review to prevent declining sales volume and cycle products as needed.

Improving Cycle Time with Six Sigma Conclusion

Upon completing the project, it was evident that the DMAIC process had immensely benefitted the company. The company achieved more efficient capacity planning by eliminating wasteful procedures and streamlining its delivery process. It also helps increase the satisfaction of its customers, distributors, and suppliers. These upturns are proof of the effectiveness of the project team’s efforts. It paves the way for a brighter future for the plumbing products company and other SMEs.

Looking at it from a financial perspective, the project proved to be a remarkable triumph. The yearly sales witnessed a significant surge of $248,034, with a major chunk of this boost attributed to a reduction of two and a half days in turnaround time. The remaining increase in sales can be attributed to enhanced precision in forecasting, with the forecast error plummeting from 57% to 31%. This improvement translated into a staggering $80,443 of the total sales increase.