Quality Function Deployment (QFD) and House of Quality (HOQ) are structured approaches for defining customer requirements and translating design specifications and product control characteristics into a planning matrix. In other words, using QFD allows the charting of customer wants and technical hows, which results in a better understanding of design relationships.

Quality Function Deployment (QFD) and House of Quality (HOQ) is a planning process for products and services that starts with the voice of the customer. Basically, it enables people to think together. You can also include a competitive analysis. People on your team will be better aligned and able to think together toward a solution.

Why Use Quality Function Deployment?

- Effectively communicate customer requirements and strategically prioritize efforts throughout the organization.

- Is a customer-driven process for planning products and services.

- Helps to identify important parameters to include in the design.

- Allows you to compare the design parameters with competitive products.

- Reduces the development time and is cost-effective.

Importance of Quality Function Deployment (QFD) and House of Quality (HOQ)

Yoji Akao first developed Quality Function Deployment in Japan in 1966. QFD helps incorporate all the customer needs into the final product in the early stages of the design phase. Furthermore, it is a planning tool to determine the key areas in which the effort should focus in relation to our technical capabilities.

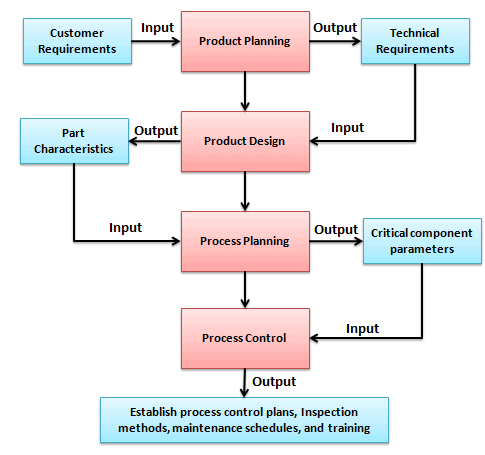

Four primary phases of QFD – Product development steps

Product planning:

- Identify customer requirements.

- Translate VOC into design specifications or product control characteristics as a planning matrix.

- Prioritize requirements.

- Evaluate competition and prioritize requirements.

Product design:

- Generate design ideas or concepts.

- Translate the outputs of the product planning phase into individual part details that define part characteristics.

- Identify product risks.

- Define the product specifications.

Process planning:

- Define the product development process and establish critical component parameters.

- Establish critical process controls.

- Create a manufacturing process flowchart and document process parameters (or target values).

Process control (production planning):

- Define the production requirements for each component/operation.

- Establish inspection and test methods.

- Define performance indicators to monitor the production process.

What is House of Quality (HOQ)?

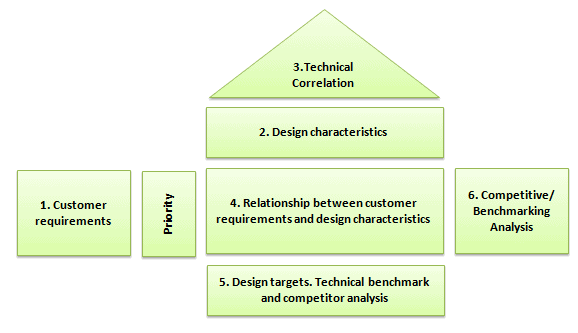

A house of quality (HOQ) involves collecting and analyzing the “voice of the customer,” and it is a key part of the Quality Functional Deployment technique. It is used to define the relationship between customer desires and the product or company’s capabilities.

Step 1: Customer Requirements – “Voice of the Customer”

The first step in a HOQ is to determine the market segments and identify prospective customers. The team collects customer requirements and rates them on a scale of 1 to 5, with 5 being the most important and 1 being the least. Then they calculate the relative importance.

Step 2: Technical measures

Product requirements or technical characteristics are aligned with the voice of the customer. This step can be quite difficult as it involves people working in groups to skim out the variables that may affect the customer requirement factors the most. Parameters should be meaningful, measurable, and global.

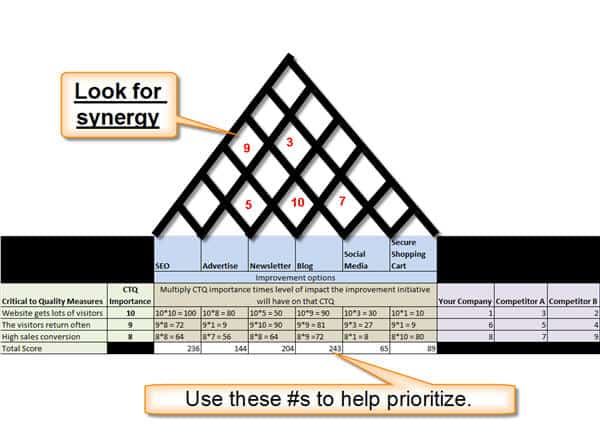

Step 3: Roof / Correlation Matrix

The triangular “roof” matrix of the House of Quality is to identify how the design requirements interact with each other. It helps the designers in the next phase of the QFD project. The triangular matrix looks like a house with a roof. The interrelations are rated strong positive as “+ +,” whereas strong negative as “- -“and blank for no interrelation.

Step 4: Relationship Matrix

Develop a correlation between customer requirements (or the voice of the customer) and the design characteristics or technical requirements. Decide the symbols you want to use to describe your desired grades. These should be consistent and easy to understand.

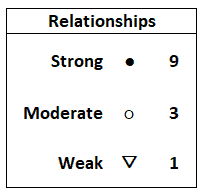

The ranking system use is a set of symbols for strong, medium, and weak relationships. Each of the symbols represents a value of 9 for strong, 3 for medium, and 1 for weak.

Step 5: Importance Rating

The Importance Rating is the result of calculating the total sum of each column when multiplied by the customer importance factor. It helps to determine where to assign the most resources. Then, calculate the percentage of importance.

Step 6: Competitive Evaluation

Competitive Evaluation helps to understand competitor products that fulfill customer requirements. It is a good idea to ask customers how the product or service rates are in relation to the competition. Use surveys, customer meetings, or focus groups/clinics to obtain feedback. Measure the satisfaction on a scale of 1 to 5, where 1 is highly dissatisfied and 5 is highly satisfied.

Identify more specific target values for technical specifications to satisfy the VOC. This section helps appropriate teams within the origination to develop next-level QFD.

Example of House of Quality (HOQ)

Quality Function Deployment functions such as House of Quality are used on consumer products to identify and manage design trade-offs. It involves studying customer requirements, which can take many forms. For example, a marketing survey that has been targeted towards a certain marketing group is a way to study customer requirements.

It may not work well for existing products, but the results are quite efficient if you consider solving a big design problem. Usually, the purpose of this survey is to find out what the consumers want from the consumers. The House of Quality is a good patch between customer requirements and engineering variables.

Example: We pick a car on which we are going to perform a house of quality analysis. Since this is a hypothetical scenario, we will assume all the data.

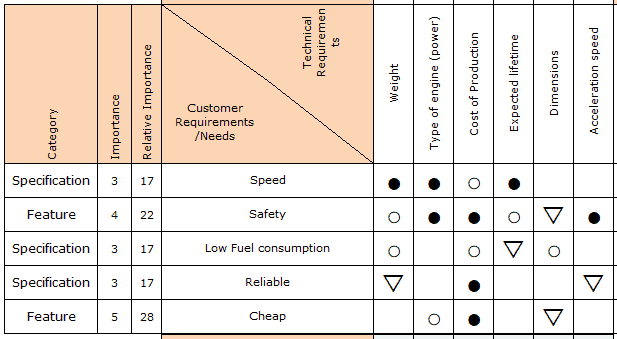

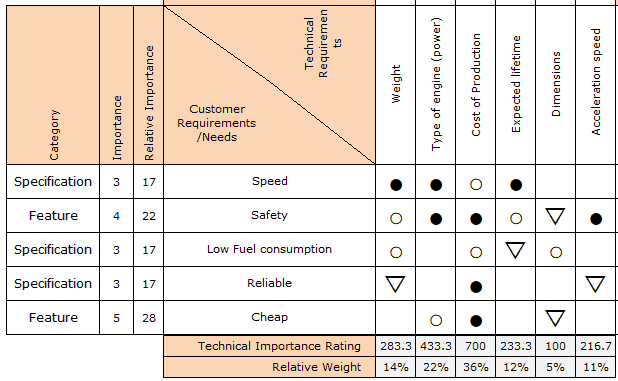

Step 1: Customer Requirements-“Voice of the Customer”

The first thing you need to decide on is the customer requirements.

For example, the minimum requirements for a car might be:

- Speed

- Safety

- Low Fuel Consumption

- Reliable

- Cheap

The next thing we do is assume the importance of each of these car characteristics, like what is important according to the customers.

For example, let us rate all of these on a scale of 1 to 5, with 5 being the most important and 1 being the least.

- Speed-3

- Safety – 4

- Low Fuel Consumption- 3

- Reliable -3

- Cheap-5

Step 2: Technical measures

The next thing you need to do is figure out the engineering parameters that you need in order to design the car.

- Weight

- Type of engine (power)

- Cost of production

- Expected lifetime

- Dimensions

- Acceleration speed

It is also a good way to help establish the importance.

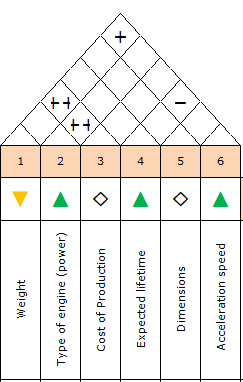

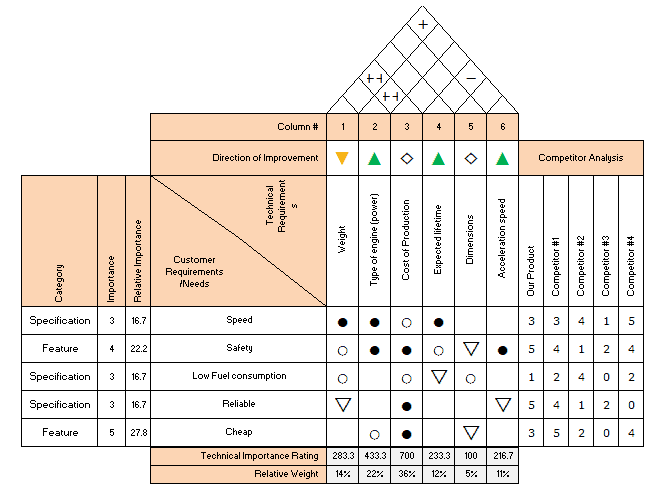

Step 3: Roof / Correlation Matrix

The first row is called up or down. In this column, you describe whether the following parameter is better with a high value or low.

For example, it is always better we have low weight, high engine power and life, low cost of production, high dimensions, and quick acceleration.

Similarly, you can now compare the effects of changing one alternative on the others. You can use symbols such as ++ to represent a strongly positive effect, + for a positive effect, 0 for no effect,– for a negative, and – – for a strongly negative effect.

Step 4: Relationship Matrix

Now fill in all the boxes of the design parameter columns. This is the largest and most difficult part of the design process.

The ranking system use is a set of symbols for strong, medium, and weak relationships. Also, each symbol represents a value of 9 for strong, 3 for medium, and 1 for weak.

E.g., rate how the weight is related to speed, fuel consumption, safety, size, reliability, and price. Do this for all the alternatives.

Step 5: Importance Rating

Sum up all of the values for each column of the engineering parameters and write the sum at the bottom of the table. This is the total importance of each individual engineering parameter.

Then calculate the percentage of importance: You add them up and then divide each importance value by the total to get the percentages. This will help you decide which parameters you need to focus on to meet the demands of the public.

It will also shed some light on the relative importance of each parameter in the design process.

Furthermore, you can use as many designs as you want and test as many alternatives as possible. It is all up to you! It all depends on the available data, the amount of detail you want to go into, and the extent to which you are willing to invest your time and resources in this process.

However, this process is very time-consuming if done manually, as many decisions must be made. Hence, you have to decide which factors are worth considering and which are not for one.

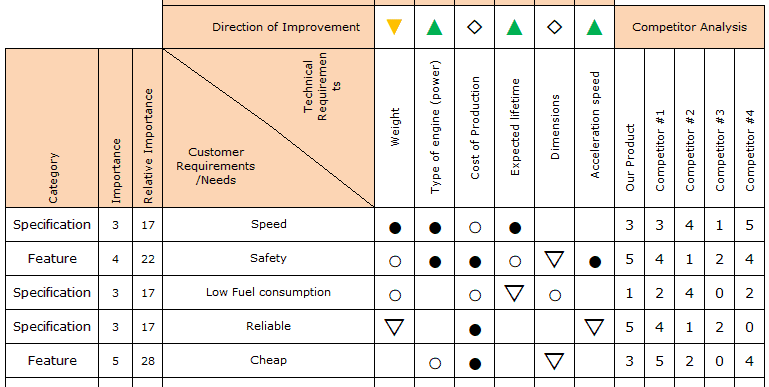

Step 6: Competitive Evaluation

Use further add-ons to compare different alternatives in order to check how the different types of cars shape up with all the other alternatives.

Use a scale of 1 to 5, with 1 being highly dissatisfied and 5 being highly satisfied. For each customer requirement, rank 1 to 5 to the competitors and also for our product (car).

Also, use this add–on to check new designs that you make and learn to select the best optimization for anything you want to make.

This also helps identify discrepancies that you may have in your designs–know what you are lacking in your design that the public requires.

This is a good way to get everything in there at once. It is also suggested that you sign it as soon as you agree on something.

QFD Template Download

Benefits of House of Quality (HOQ)

- Improves performance of the products

- Reduces implementation time

- Reduces warranty and service costs

- Promotes teamwork

- Enables understanding of the competition

Quality Functional Design and House of Quality Videos

Six Sigma Black Belt Certification QFD Questions:

Question: Which of the following tools is used extensively in quality function deployment (QFD)?

(A) Affinity diagram

(B) Matrix diagram

(C) Cause and effect diagram

(D) Activity network diagram

Answer:

When you’re ready, there are a few ways I can help:

First, join 30,000+ other Six Sigma professionals by subscribing to my email newsletter. A short read every Monday to start your work week off correctly. Always free.

—

If you’re looking to pass your Six Sigma Green Belt or Black Belt exams, I’d recommend starting with my affordable study guide:

1)→ 🟢Pass Your Six Sigma Green Belt

2)→ ⚫Pass Your Six Sigma Black Belt

You’ve spent so much effort learning Lean Six Sigma. Why leave passing your certification exam up to chance? This comprehensive study guide offers 1,000+ exam-like questions for Green Belts (2,000+ for Black Belts) with full answer walkthroughs, access to instructors, detailed study material, and more.

Comments (32)

How we can draw roof matrix. please give detail about roof matrix.

Abhay – I’ve added detailed videos. Hope this helps!

Update: We added step-by-step instructions via text and images above. Does this help?

what are the relationships between house of quality and quality function deployment

Good question. The House of Quality is sometimes referred to as a Quality Function Deployment Matrix. The House of Quality is the first chart used in Quality Function Deployment to design an improvement for a product or a service.

How to comment on portance weighting in qfd?

In Quality Function Deployment (QFD), portance weighting—also known as importance weighting—helps prioritize customer requirements based on their relative significance. After collecting the “Voice of the Customer,” each requirement is assigned an importance rating, typically on a scale (e.g., 1 to 5 or 1 to 10). These ratings then inform how design characteristics (the “hows”) are prioritized to meet the most critical customer needs.

The importance weightings are crucial because they guide resource allocation, ensuring that the most valued features receive the necessary focus. When combined with relationship strength (strong, medium, or weak correlations) and technical difficulty, these weights help derive a weighted score for each design requirement.

I am doing a DMADV project which is itself something new to the industry. I don’t have any data regarding this because it is proposed a modification in which I got 4 options. Out of these four options, I need to select one.

I have customized house of quality in such a way that I became the customer because I know my desires and CTQs so, I built QFD of all four options. now I need to select one best option.

Can I do it like this ???? What is the roof of QFD says?

Absolutely. What you’re doing is quite valid within the DMADV framework, especially in the early design stages where historical data may be limited or unavailable. Since you’re introducing something new to the industry, it’s perfectly reasonable to rely on expert judgment and structured tools like the House of Quality in QFD to guide decision-making.

By becoming the “customer” and mapping your known CTQs (Critical to Quality characteristics), you’ve adapted QFD to suit your context—this is not only acceptable but also encouraged in design projects where customer insights need to be approximated or are internally derived.

The **roof of the QFD** plays a key role in your analysis. It identifies the **correlation between design features (the “hows”)**. Strong positive or negative relationships highlighted in the roof help you understand how changing one feature might impact others. This is especially helpful when you’re comparing options—because it reveals potential conflicts or synergies that could influence performance, cost, or feasibility.

If you’ve completed the QFD for all four options, you can use the **weighted importance scores**, derived from how well each option satisfies the CTQs, to select the best candidate. The roof can act as a secondary decision layer, helping you understand trade-offs and avoid unintended consequences.

Can I have a training schedule for the following: quality Technician

Sorry, Marcelleno. I do not currently offer training.

how is House of quality related to engineering?

Hi Tim, one way I would look at it is via my half-remembered IBM quote “There are no engineering solutions, there are only business solutions.”

By that I mean QFD and HOQ can help you prioritize what is built so that less waste occurs AND value delivered is maximized.

can i get house of quality example for specific product

I’ll add this request to the backlog, Wahi.

Update: We added step-by-step instructions via text and images above. Does this help?

thank you sixsigmastudyguide for giving me wonderful information

Glad it helps, Rohit!

Is the interrelationship same with the roof of the HOQ?How are we going to build HOQ for cookies company whereby we have a voice of customer and technical features.How we gonna relate both VOC and technical featuree to create interrelationship and relationship matrix?

Fiya,

In the House of Quality (HOQ), the relationship matrix and the roof (interrelationship matrix) serve two distinct but complementary purposes:

Building a HOQ for a Cookie Company

Let’s walk through a simplified version of how to do this:

Step 1: Gather VOC

Collect customer feedback—maybe through surveys or focus groups. Example VOCs could be:

Step 2: Identify Technical Features

These are things your team can control during production. Examples might be:

Step 3: Build the Relationship Matrix

For each VOC, rate how strongly each technical feature impacts it:

This matrix quantifies how well your technical efforts satisfy customer needs.

Step 4: Add the Roof

Now analyze how technical features affect one another. For example:

Understanding these interrelationships helps you avoid technical trade-offs that could compromise customer satisfaction.

You can explore more examples and applications of QFD in our article on

Quality Function Deployment (QFD).

Best, Ted

Construct a QFD house of quality diagram for Online/ blended education service provider of your choice (e.g. NPTEL, Swayam). How can this be done

Kailash,

Have you tried following the directions above? Can you share how far you’ve gotten?

Best, Ted

Are there any other tools apart from QFD which can be used to translate the customer requirements into technical specifications?

And, what are the implications of the roof of Matrix, or the relationship of HOWs versus HOWs?

Excellent questions! Translating customer requirements (VOC) into technical specifications is a core challenge in product and process design. While QFD is the most structured and visual approach, there are several other tools that can support or complement this process:

Alternative Tools to Translate VOC into Technical Specifications

These tools can be used in conjunction with or as precursors to QFD, especially in DMADV projects where clear linkage between VOC and design specs is critical.

Implications of the Roof of the HOQ (Interrelationship Matrix)

The roof of the House of Quality (HOQ) shows the relationships between the technical requirements themselves—the HOWs vs. HOWs. Here’s what it helps you understand:

Understanding the roof ensures that technical decisions made to satisfy customer needs do not unintentionally conflict or create inefficiencies. It enhances design, which is a key goal in the DMADV methodology.

Hi, I have a question on weighting the CTS in HoQ #2. In HoQ #1 we weight the VoC by questioning the customer right? then do we have to do the same thing on the HoQ #2 to weight the CTS or could we just refer to certain value in the HoQ #1?

Thank you

Hi Gede Keresnadi,

For HOQ#2, you’ll identify design requirements or technical measures for the product, such as weight, cost of production, and operating system. Once you identify the design requirements or technical measures, then you’ll identify how strongly each of the design parameters affects the customer’s need (step#4)– relationship matrix.

Thanks

How does the House of Quality model apply to service provision, for example, the police service

Yes. HOQ can apply to any organization that has a strong client-centric focus.

Happy to coach you through. Can you list a few items that a police service clients’ might have strong desire for?

Thank you for this detailed article covering all the aspects

You’re welcome, Mashuk.

Thank you … you open my eyes in a new field

Welcome, Adele.