IDDOV is one of the models of DFSS to achieve Six Sigma performance which starts with the customer and ends with the customer. IDDOV takes the existing DEFINE phase and divides it into two modules with Identify focusing on translating customer needs into the design of the product. At the same time, Define ensures the product specifications meet the consumer’s needs.

Essentially, IDDOV includes more upfront work to establish customer requirements and translates them into the product design. IDDOV also contains the same elements of Design and Optimize as found in DMADOV.

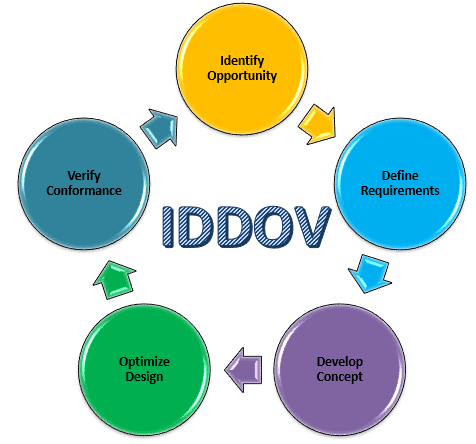

The five phases of IDDOV are Identify, Define, Develop, Optimize, and Verify.

- Identify: Identify the opportunity

- Define: Define the requirements

- Develop: Develop the concept

- Optimize: Optimize the design

- Verify: Verify conformance

DFSS is the widely used systematic and disciplined framework for product development. Furthermore, various models that utilize DFSS for robust engineering design such as DMADV (Define, Measure, Analyze, Design, and Verify), CDOV (Concept, Design, Optimize, Verify), DMEDI (Define, Measure, Explore, Develop, Implement), and IDDOV (Identify, Define, Develop, Optimize and Verify). While every method has pros and cons, organizations will choose the appropriate DFSS model depending on the scenario.

What is Design for Six Sigma (DFSS)

Use DFSS when the business is seeking to build a new product, service, or process. Design for Six Sigma is effective in that it takes all the guesswork out of designing new goods for customers. Designing new goods can be a daunting task since no feedback exists that is commonly available in DMAIC. Often this leads to companies spending LOTS of money designing something in trial and error in order to build the best characteristics for this new good. But with DFSS, customer needs are built into the design of the product upfront.

When Should you Use DFSS Over DMAIC?

Six Sigma aims to improve the existing designs, whereas DFSS focuses on creating new and better products.

Use Design for Six Sigma when:

- The business outcome is showing ‘stair shaped graphs’

- Building new products, services, processes

- Exponential change to an existing system

- Introduction of new technology to the business

Phases of IDDOV

1. Identify Opportunity

Identifying the business opportunity is the first and also important phase of IDDOV. In this phase, gather the voice of the customer, prioritize the needs, and then translate them into design requirements. Finally, create a project plan and project charter after requirements are identified. The performance of all future activities depends on the effectiveness of the phase.

Key Tools

- Voice of customer: Understanding customer needs is critical for business success. Furthermore, organizations must contact customers constantly. Collecting the voice of customers is a multi-level task.

- Project Charter: The project charter is a set of documents that provide purpose and motivation for the initiative, serves as a working document for the team and as a reference for the rest of the company, and it also acts as a guiding hand for the Plan-Do-Study-Act cycle (Deming wheel, Shewhart wheel).

- Project Plan: A project plan is an in-depth list of the tasks, resources, and management decisions required to complete the project.

2. Define Requirements

Examine the customer needs and requirements and then define the product requirements. In other words, translate the customer requirements into verifiable product requirements.

Key Tools

- QFD: Quality Function Deployment (QFD) and House of Quality (HOQ) is a structured approach for defining customer requirements and translating design specifications or product control characteristics in the form of a planning matrix.

3. Develop the concept

Develop all feasible concepts, evaluate them, and then finalize the best concept that meets customer requirements. Look for alternate options if the concepts do not suit the requirement. Moreover, all the potential failures are addressed in this phase.

Key Tools

- Brainstorming: Brainstorming is a method for generating a large number of creative ideas in a short period of time.

- TRIZ: TRIZ takes what is already created, adapts, and deploys it to solve today’s problems. Moreover, TRIZ uses tables of inherent contradictions and innovation principles, not trial-and-error to reform the design challenge and remove physical contradictions.

- Pugh Concept selection: The Pugh Analysis Matrix is an analysis tool that results in an optimal concept. In other words, it refines a list of ideas using a matrix-based process to weigh and compare the conceptual designs.

- DFX – Design for X: Design for Excellence (aka Design for X, DFX) is a systematic approach for achieving a target objective. X represents the target objectives or characteristics of the product or process.

4. Optimize the Design

Optimize the design that produces the maximum output. Use the statistical and process capability methods to build parameters and tolerances. Furthermore, develop detailed designs and functional parameters that meet the customer’s needs and expectations.

Key Tools

- Process Capability: Process Capability Analysis tells us how well a process meets a set of specification limits based on a sample of data taken from a process. Also, it can be used to establish a baseline for the process and measure the future state performance of the process for comparison.

- DOE: Design of Experiments is a topic that is difficult for many Six Sigma certificate applicants to master. Not to worry, we’ve got you covered with a comprehensive study guide.

- Taguchi Robust Design: Robust design has been the key development in the design process in recent years. The robust approach in design is a key aspect as it produces reliable design both during manufacturing and during product use. The basic concept of robust design is that parameter control that makes the design strong enough that it does not cause failure due to random “noise”

5. Verify Conformance

Verify the performance of the product and validate as per the defined process controls. Monitor the process performance over time and implement appropriate controls to meet customer requirements.

Key Tools

- SPC: Statistical Process Control (SPC) is a statistical method to measure, monitor, and control a process. In other words, SPC is a method of quality control that employs statistical methods to measure, monitor, and control a process. It is a scientific visual method to monitor, control, and improve the process by eliminating special cause variation in a process.

- FMEA: Failure Mode Effects Analysis (FMEA) is a tool that helps us anticipate what might go wrong with a product or process. We can also use it to identify the possible causes and probabilities of failures.

Benefits of IDDOV

- Quicker product launches

- Quality design

- Less product cost

- Improved Quality and Reliability

- Avoids risk factors

- Reduced Product Cost