What is a Cumulative Sum Chart?

A cumulative sum chart (CUSUM) is a type of control chart used to detect the deviation of the individual values or subgroup mean from the adjusted target value. In other words, monitor the deviation from the target value. CUSUM chart is an alternative to Shewhart control charts.

The basic advantage of the CUSUM chart is that it is more sensitive to the small shift of the process means when compared to the Shewhart charts (Individuals I-MR or Xbar charts).”

The cumulative sum chart and the exponentially weighted moving average (EWMA) charts also monitor the mean of the process, but the basic difference is unlike Xbar charts. They consider the previous value means at each point. Moreover, these charts are considered a reliable estimate when the correct standard deviation exists.

When Would You Use a Cumulative Sum Chart?

The purpose of the CUSUM chart is to monitor the small shift in the process mean of the samples collected at time intervals. These measurements of samples at a given time interval represent the subgroups.

Instead of calculating the subgroup’s mean independently, the CUSUM chart represents the information from current and previous samples. Hence, the CUSUM chart is always better than the Xbar charts in detecting the small shifts of process mean.

The CUSUM chart is more effective when the sample size is one. These charts are basically used in process industries and in manufacturing.

When using subgroups (n > 1), you can still use CUSUM effectively by adjusting the standard deviation to reflect the sampling distribution of the mean. This flexibility makes CUSUM suitable across different sampling strategies, as long as you calibrate the decision interval H appropriately.

Comparison between CUSUM and Shewhart chart

The purpose of the CUSUM and Shewhart charts is to detect the mean shifts in the process; the basic differences are:

- CUSUM charts consider all the samples up to a current point and also consider the current sample for measurement, whereas the Shewhart chart is based on the single subgroup measurement.

- The determination of the out-of-control limit in CUSUM charts is based on the decision interval or the use of the V-Mask method, whereas the Shewhart chart is based on control limits (upper and lower control limits).

- CUSUM charts’ control limits are computed from average run length specs, whereas the Shewhart chart control limits are generally at the three-sigma limits.

Advantages of the CUSUM chart

- CUSUM charts are the best way to detect the small shifts in process mean, especially 0.5 to 2 SD from the target mean.

- It is easy to identify the shifts in the process visually.

Disadvantages of the CUSUM chart

- Establishing and maintaining CUSUM charts is more complicated.

- CUSUM charts are slower in detecting large process mean shifts.

- Since CUSUMs are correlated, it is tough to interpret the patterns.

How do you make a Cumulative Sum Chart?

The CUSUM charts can be represented in the visual method, i.e., V-mask. This method was introduced by Barnard in 1959 to check whether a process is out of control or not. Still, the generally tabular (algorithmic) method will be used to monitor the process. Unlike other standard control charts, all previous measurements for CUSUM charts are included in the calculation for the latest plot. But, establishing and maintaining the CUSUM is difficult.

V-Mask Method

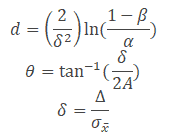

V-mask looks like a sideways V. The V-mask chart checks whether each marked sample falls within the boundaries of the V-mark. If any point falls outside of the control limit, that indicates a signal mean shift in the process. When each sample is plotted, the V-mask may have shifted to the right. The below graph shows the V-mask and related formulas.

The behavior of the V-Mask is determined by the distance k (which is the slope of the lower arm) and the rise distance h. The team could also specify d and the vertex angle (or, as is more common in the literature, q = 1/2 the vertex angle). For an alpha and beta design approach, we must specify

- α, the probability of concluding that a shift in the process has occurred, when in fact, it did not.

- β, the probability of not detecting that a shift in the process mean has, in fact, occurred.

- δ (delta), the detection level for a shift in the process mean, expressed as a multiple of the standard deviation of the data points.

Tabular Method

The Tabular method is an easier method than the V-Mask method. Here are the steps to make a CUSUM chart.

- First of all, estimate the standard deviation of the data from the moving range control chart σ= R̅/d2.

- If you are working with subgroups of size n > 1, adjust the process standard deviation using:

σmean = σ / √n, This gives you the standard deviation of the sample means rather than the individual values, ensuring that your decision interval H remains accurate for subgrouped data.

- If you are working with subgroups of size n > 1, adjust the process standard deviation using:

- Calculate the reference value or allowable slack since the CUSUM chart monitors the small shifts. Generally, 0.5 to 1 sigma will be considered. K= 0.5 σ.

- Compute decision interval H, generally ± 4 σ will be considered (some place ± 5 σ also be used).

- Selecting the decision interval H is crucial because it determines the chart’s sensitivity to detecting process mean shifts. A smaller H (e.g., 4σ) makes the chart more sensitive and faster to detect small shifts, but it may increase false alarms. A larger H (e.g., 5σ) reduces false positives but may delay detection. This balance directly affects the Average Run Length (ARL), which is a measure of expected performance in detecting changes.

- Calculate the upper and lower CUSUM values for each individual i value.

- Upper CUSUM (UCi)= Max[0, UCi-1+xi – Target value-k).

- Lower CUSUM (LCi)= Min[0, LCi-1+xi – Target value+k).

- Draw all UCi & LCi values in the graph and also draw decision intervals (UCL and LCL).

- Check if any of the UCi values are above the UCL and any of the LCi values are below the LCL.

- Finally, take necessary action to eliminate the special causes if any of the points are out of control limits.

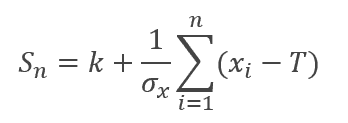

Calculate the plotting position

To find the plotting position for the new point in a cumulative sum chart, you can use the following formula.

Where:

- Sn= Plotting Position

- k = reference value or the center line of the cumulative sum chart (if provided)

- xi = The new point you want to plot

- T=Target value

- σx = Std Dev

Example: Find the plotting position for the new point 80 in the cumulative sum chart for the standard deviation 5, target value 70 and k=0.5.

To find the plotting position for the new point of 80 in a cumulative sum chart, you can use the following formula:

Plotting position = k + [(xi – Target value) /σ]

Where:

k = 0.5 (the center line of the cumulative sum chart)

xi = 80 (the new point you want to plot)

Target value = 70 (the target value for the process)

σ= 5 (the standard deviation of the process)

So,

Plotting position = 0.5 + [(80 – 70) / 5]

Plotting position = 0.5+2=2.5

Therefore, the plotting position for the new point of xi = 80 in the cumulative sum chart is 2.5.

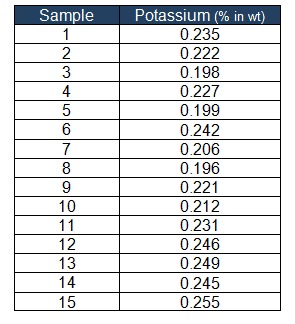

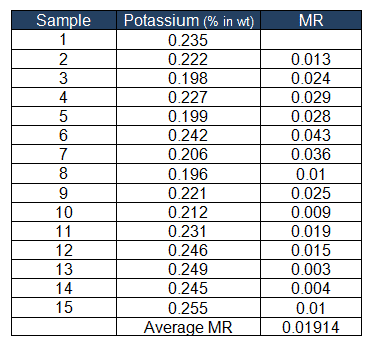

Example of Using a Cumulative Sum Chart in a DMAIC Project

Example: CUSUM chart will be used in the control phase of DMAIC. In a drug manufacturing unit, potassium content is one of the important parameters. The target potassium content is 0.21% in wt. Therefore, the team has collected 25 batches from the production in a time interval to monitor the process mean shift.

Step1:

Estimate the standard deviation of the data from the moving range control chart σ= R̅/d2.

- n=2

- d2 = 1.128

- σ= R̅/d2 = 0.01914/1.128 = 0.0169

Refer to common factors for various control charts.

Step 2:

Calculate the reference value or allowable slack K= 0.5 σ = 0.5*0.0169 = 0.00848

Step 3:

Compute decision interval H, generally ± 4 σ = ± 4 * 0.0169= ± 0.0679

UCL = +0.0679 and LCL = -0.00679

Step 4:

Calculate the upper and lower CUSUM values for each individual i value.

Target value =0.21

Upper CUSUM (UCi)= Max[0, UCi-1+xi – Target value-k)

Lower CUSUM (LCi)= Min[0, LCi-1+xi – Target value+k)

For the first sample: 0.235

- Upper CUSUM (UC1)= Max[0, 0+0.235– 0.21-0.0084) =0.017

- Lower CUSUM (LC1)= Min[0, 0+0.235-0.21+0.00848) = 0

For the second sample: 0.222

- Upper CUSUM (UC1)= Max[0, 0.017+0.222– 0.21-0.0084) =0.02

- Lower CUSUM (LC1)= Min[0, 0+0.0222-0.21+0.0084) = 0

Similarly, find the Upper and Lower CUSUM for all the samples:

Step 5:

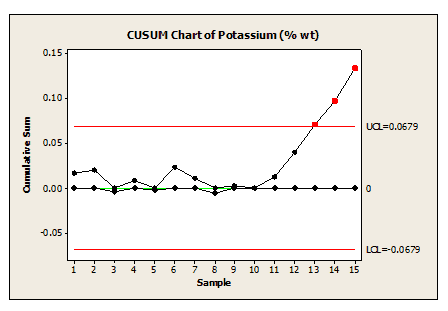

Draw all UCi & LCi values in the graph and also draw the decision intervals (UCL and LCL).

Step 6:

Conclusion: It is clearly evident from the above graph that from sample 13 onwards the process is going out of control. Hence, the team has to identify the special cause and take the appropriate corrective action.

Generic Example for Setting k and H

Suppose your target value is 370, and you want to detect a shift of 1 standard deviation. Assume your estimated process standard deviation (σ) is 10, and your subgroup size (n) is 4.

- Reference value (k): Half of the shift to detect → k = 0.5 × σ = 0.5 × 10 = 5

- Adjusted standard deviation for subgroup mean: σmean = 10 / √4 = 5

- Decision interval (H): Typically 4 to 5 times σmean → H = 5 × 5 = 25

So, for this setup, you would use k = 5 and H = 25. This allows for better customization of the CUSUM chart when working with various subgroup sizes.

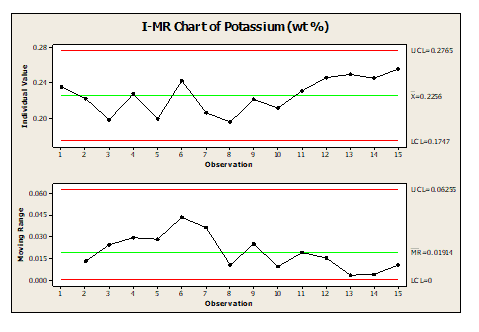

Compare a CUSUM example with a Shewhart Chart.

Furthermore, use a sample example from the above and draw the Individual I-MR.

From the above graph, it is clearly evident that both the Individual and Moving range process is in control and predictable. Still, the sample example CUSUM chart shows the process is going out of control. Hence, CUSUM charts are more effective in monitoring the small shifts in the process mean than Individuals I-MR or Xbar charts.

What Do You Need to Know for Your Exam?

Green Belts

The IASSC Green Belt BOK requires you to know EWMAs as part of Statistical Process Control.

Black Belts

The Villanova Black Belt BOK notes you are required to “Understand appropriate uses of short-run SPC, EWMA, CuSum, and moving average.”

The IASSC Black Belt BOK lists CUSUM Charts under what’s needed for 5.2 Statistical Process Control (SPC).

Cumulative Sum Chart Videos

Helpful Links

When you’re ready, there are a few ways I can help:

First, join 30,000+ other Six Sigma professionals by subscribing to my email newsletter. A short read every Monday to start your work week off correctly. Always free.

—

If you’re looking to pass your Six Sigma Green Belt or Black Belt exams, I’d recommend starting with my affordable study guide:

1)→ 🟢Pass Your Six Sigma Green Belt

2)→ ⚫Pass Your Six Sigma Black Belt

You’ve spent so much effort learning Lean Six Sigma. Why leave passing your certification exam up to chance? This comprehensive study guide offers 1,000+ exam-like questions for Green Belts (2,000+ for Black Belts) with full answer walkthroughs, access to instructors, detailed study material, and more.

Comments (17)

Hi everyone,

On the IASSC Reference document, subject Cusum chart,

its equation is (please see attachment)

Sn = (1/σX)*[sum(i=1 to n)(Xi-T)]

it describes Sn as “plotting position”

does anyone know what this equation is about?

it is not mentioned anywhere on the notes of this section:

https://sixsigmastudyguide.com/cumulative-sum-chart-cusum/

Thank you,

XL

Hi Xiang,

I see what you’re referring to in the IASSC reference document.

We’ll update this reference article with a walkthrough of the equation. In the meantime, please refer to your Six Sigma training materials.

Best, Ted

Hi,

Has there been an updated on this reference article to walk us through the Sn = (1/σX)*[sum(i=1 to n)(Xi-T)] equation used in the IASSC Reference document? It would be really helpful.

Thanks.

I am also keen to figure out how to use this equation with the reference to a plotting position. In the six sigma black belt exam (IASSC) you are provided with the following

k=0.5

Target value = 50

Std Dev = 5

And then the question asks you to find the Plotting position for the new point of Y = 55

Any help would be appreciated

Hi Alison,

To find the plotting position for the new point of Y or xi= 55 in a cumulative sum chart, you can use the following formula:

Plotting position = k + [(xi – Target value) /σ]

Where:

k = 0.5 (the center line of the cumulative sum chart)

xi = 55 (the new point you want to plot)

Target value = 50 (the target value for the process)

σ= 5 (the standard deviation of the process)

So,

Plotting position = 0.5 + [(55 – 50) / 5]

Plotting position = 1.5

Therefore, the plotting position for the new point of xi = 55 in the cumulative sum chart is 1.5.

Thanks Ramana PV for the workings. The IASSC eval exam says the correct answer to this question is .250 rather than your answer of 1.5.

Not sure how the IASSC answer has been calculated, any help is appreciated, thanks!

Can you share how they came to their answer?

Paragraph 6 says, “The purpose of both cumulative sum chart (CUSUM) and Shewhart charts are to detect the mean shits in the process”.

You must have meant, “mean shifts”, since what you wrote is a swear word and is never appropriate for use in a proper business context.

Please edit to remove the vulgar reference to excrement.

Oh, this is hilarious. Thanks for pointing it out. Updating now.

Hi, I want to ask a question about CUSUM parameters. There are two parameters one is a reference value, and the other is a decision value. The reference value is half of the target value, and the decision value is the guess value, but how do we select the decision value? Which method or technique is used for that. I’m working on a CUSUM control chart; my target value is 370. How I select decision value ”H” at different sample size and subgroup size

Great question! In a CUSUM control chart, the two key parameters are:

To determine H, start by estimating your process standard deviation (σ). If you are working with subgroup data, adjust the standard deviation for the sample means using:

Then, calculate H as a multiple of σmean. For example, if your target value is 370, σ = 10, and subgroup size is 4:

This gives you a well-calibrated decision interval based on your process characteristics.

We’ve just updated this page with more details on how to select H and k, including examples for both individual and subgroup data. Check it out for a step-by-step walkthrough!

And thank you for the question!

Hello ur article helped me a lot now I understand how a CUSUM works. But my Prof used another fromula. And i dont unterstand it. I hope u can help me:

Z_i=(x ̅_i-x ̅ ̅)/(s ̅/(c_4 √n))

and then he wrote this:

S_H (ⅈ)=max[0,(Z_i-k)+S_H (i-1)]

S_L (ⅈ)=min[0,(-Z_i-k)+S_L (i-1)]

I dont unterstand his formula. Urs makes much more sense. Thanks for the help

Hi Luke,

I’m glad the article helped!

I’m not staffed to help in this manner. Perhaps you can work with your professor and share your learnings back here?

Best, Ted.

Hi Ted,

In step 4 you mention:

Lower CUSUM (LC1)= Min[0, 0+0.0235-0.21+0.00848) = 0

Where do you get the 0.0235? The rest of the math makes sense but I can’t seem to figure out where this number is coming from. I see for the Upper CUMSUM you use 0.235, not sure on the difference.

TIA

Thank you, Bill, corrected the Lower CUSUM (LC1) formula.

Thanks

Hello! I am curious about how you calculate the d2 value?

Technically, it’s derived from numerical integration (more here.)

For most purposes, it’s fine just to use the chart I put on the page. Here’s the source from the chart.