Cost of Poor Quality (COPQ) is the cost associated with producing poor-quality products or services for the customer. In other words, it is the total financial losses incurred by the company due to errors and subpar work. For example, scrap, rework, repair, and warranty failure all add to the cost of poor quality.

Cost of Quality is a methodology used in the organization to measure the resources used for good quality. In other words, it is the cost of making quality products or services.

Cost of Quality combines the cost of good quality and the cost of poor quality.

Why Cost of Poor Quality (COPQ) Matters

- It tells how profit is affected by the quality.

- Speaks management’s language.

- Helps to prioritize improvement actions

- Optimize the resources and also help identify waste in the system.

- Improves continuous improvement culture

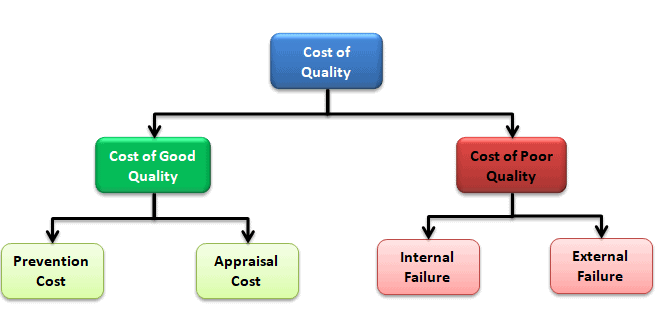

Categories of Cost of Quality

The cost of quality can be divided into four categories: prevention cost, appraisal cost, internal failure cost, and external failure cost.

Preventive Cost– Preventive costs are the costs of activities that are specially designed to prevent poor quality of products or services. In other words, these efforts ensure that failures never happen in the first place.

- Quality planning

- Contract review

- Trainings

- Quality audits

- Supplier evaluation

- Market research

- Process capability studies

Appraisal costs–Appraisal costs are incurred when the company pays a consultant or expert to find the causes of the poor quality of the product or service. In other words, appraisal costs are related to testing, measuring, and auditing. The appraisal cost focuses on the discovery of defects rather than the prevention of defects.

- Incoming goods inspection

- In-process inspection

- Supplier inspection

- Laboratory testing

- Final goods inspection

- Calibration

Internal failure–Internal failure costs result from the finding of defects prior to delivery of the product or service to the customers. In addition, these are the costs due to the failure of a product to achieve the required quality standards.

- Rework

- Repair

- Internal scrap

- Re-testing

- Efforts spent on failure analysis

- Raw material rejects

- In-process rejects

External failure–External failure costs arise from the rejection of the product or services by the customers after delivery. In other words, these are the costs when a product or service fails to meet the required quality standards and is detected after it reaches the customer.

- Warranty claims

- Customer visits

- Penalties

- Replacements

- Investigations

- Loss of goodwill

When to use Cost of Poor Quality (COPQ)

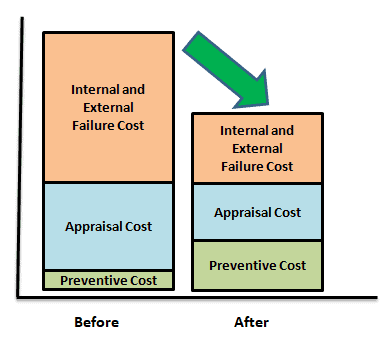

Organizations use COPQ to understand the opportunities to improve quality by reducing internal and external failure costs. They do this by spending more on preventing problems than fixing them.

Steps in implementing Cost of Poor Quality (COPQ)

- Define the organization’s quality goals and objectives

- Estimate the current capabilities of machines, systems, and processes

- Collect data for prevention cost, appraisal cost, internal failure cost, and external failure cost.

- Validate the quality cost data with finance

- Pareto the quality costs and adopt an action-first mindset

- Implement corrective actions such as automating the quality audits, streamlining the inspection process, implementing Poka-Yoke, etc.

- Compare the quality costs before and after you have implemented the above steps. Check out the figure shown below for an example.

- Finally, present the new quality cost model to top management.

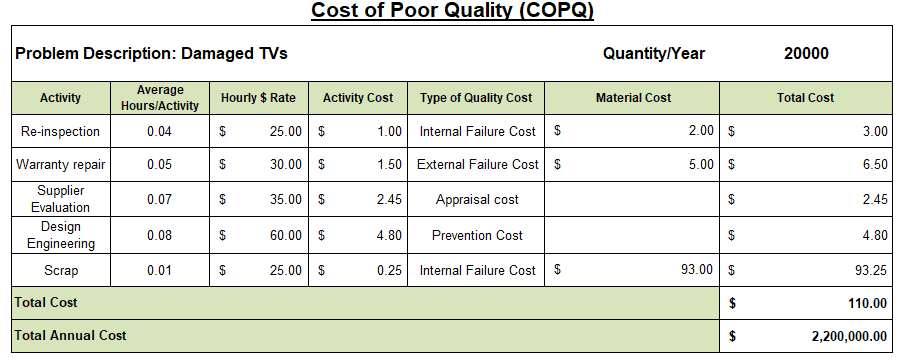

Example of Cost of Poor Quality (COPQ)

Quality assurance is everything for an organization. Incorporating Six Sigma and other Lean tools allows companies to reduce waste (Raw materials, Logistics costs, and unnecessary man hrs) which increases their bottom line.

Let’s say you are running a DMAIC project. In the define phase, you want to quantify the cost of poor quality. You start by defining what a defect is. Then, you measure how many defects per million opportunities your process has (You would use this same material to create your baseline sigma in the measure phase, next).

Example: Imagine producing TVs, and for every 1M produced, 2% were damaged. That’s 20,000 TVs. If those damages were not salvageable, and it cost $100 to produce each unit, then it costs your company 20k *$100 = $2 Million.

But that’s not all. How many people would you need to hire for re-inspection, warranty repair, supplier evaluation, etc.? Here you go for the breakup of the costs. Below is the split-up of various costs (Just as an example).

Total material cost is $100 per unit, and an additional $10 per unit is spent on quality costs. At 20k units, that is $200k. The total cost to the company would be $2.2 Million!

Cost of Poor Quality Template

D: Service and repair policies. Customers will never be exposed to internal audit results. We can eliminate C off the bat. Unfortunately, plenty of companies are out there performing well financially with poor quality items or services (until a disruptor with great quality comes along!) Very few customers will be familiar with industry standards or privy to how a company measures against them. However, if a customer sees a strong and robust service policy and a company standing behind its product, then they know the company values quality.

When you’re ready, there are a few ways I can help:

First, join 30,000+ other Six Sigma professionals by subscribing to my email newsletter. A short read every Monday to start your work week off correctly. Always free.

—

If you’re looking to pass your Six Sigma Green Belt or Black Belt exams, I’d recommend starting with my affordable study guide:

1)→ 🟢Pass Your Six Sigma Green Belt

2)→ ⚫Pass Your Six Sigma Black Belt

You’ve spent so much effort learning Lean Six Sigma. Why leave passing your certification exam up to chance? This comprehensive study guide offers 1,000+ exam-like questions for Green Belts (2,000+ for Black Belts) with full answer walkthroughs, access to instructors, detailed study material, and more.

Comments (14)

Quality is free is an awesome book. I have made a lot of money from that book.

That’s awesome to hear, Kevin!

Hi Ted,

According to IASSC,

COPQ does not include detection and prevention cost.

Detection and prevention cost are 2 parts of COGQ (cost of good quality)

Thanks,

Xiang Liu

Hi Xiang,

Can you provide a reference to that? My understanding is that IASSC does NOT provide training materials and merely audits existing trainers who wish to have their seal which leads to discrepancies between instructors. I’m happy to be wrong here but I need a reference to improve my understanding.

Best, Ted

Hi Ted,

I did its official practice test.

“COPQ does not include detection and prevention cost.”

You chose: B)

A) True

B) False

Correct Answer: A)

It is also on ASQ page:

https://asq.org/quality-resources/cost-of-quality

Best,

Xiang

Thanks for the notes, Xiang,

We’ll be sure to add those points to the article the next time we re-write it.

Best, Ted.

Under which cost should we capture the good will and free of cost materials given to customers.

Goodwill and free-of-cost materials given to customers should generally be captured under Cost of Quality (CoQ), specifically within the External Failure Costs or possibly Appraisal/Prevention Costs, depending on the intent.

If you’re referring to accounting goodwill (from acquiring another business), that’s handled separately under intangible assets and not in CoQ metrics.

I am preparing for a green belt, and it is really getting overwhelming and annoying whenever I get so in-depth into a concept just to find the question at the end of the page saying it is related to black belt training. I know it will benefit me in the long run once I get my black belt, hopefully. But as of now, I wish there were tailored content just for green belt. There is no need to waste time on difficult aspects of a topic when the exam will only scratch the surface. You could take what I’m about to say next as a compliment, but I feel like I’m getting more than I have paid for, and its both a blessing and a curse. I am really getting dizzy trying to understand whether I should put more effort in or skip some details, as it seems for the BBSS.

kind regards,

Haneen.

Haneen,

I understand your wish to focus on your training for your green belt. The practice questions, quizzes, and tests you signed up for are targeted to the belt in the program.

The underlying reference pages are comprehensive for the subject. They are there for reference, not for instruction. The questions in your practice should have concise answers to the problem at hand. The links go to the more in-depth pages to supplement your experience.

You should also have had Six Sigma training before taking this review course.

D

Thanks, Toufic.

Hello Ted,

Recently I signed up for your newsletter after having seen your blog.

In your travels, have you come across a ranking / benchmark of COPQ across industries / sectors, e.g. aerospace & defense, life sciences, high tech? if not, would you have suggestions as to where to locate this information? Thanks in advance.

Hi Bill,

I don’t know of a benchmarking system, but this principle is discussed under different names.

For instance, in software development, it’s vastly cheaper to discover a bug earlier than later.

Example of cost comparison (based on IBM research):

Design phase: Cost to fix a bug – relatively low

Implementation phase: Cost to fix a bug – 6 times higher than design phase

Post-release: Cost to fix a bug – 4-5 times higher than design phase, potentially even 100 times more during maintenance

Hope this helps!

Best, Ted.