Genichi Taguchi contributed several important concepts to the field of quality. These include the Taguchi Loss Function and Taguchi Robust design.

Taguchi was born in 1924 in the city of Takamachi, Japan. The city is known for its textile industry. His family ran a kimono business. He was expected to take the reins when it was passed down to him. Before he was able to do so, however, he received a draft notice in the mail. He had been called to serve his country’s armed forces. During his time in the military, Taguchi developed an interest in statistics. Whenever he had downtime, Taguchi read books on statistics. When the war ended, Taguchi’s love for statistics did not diminish. He met up with a well-known statistician and expanded his knowledge of applied statistics. With his background, it was natural that he should then apply what he’d learned to manufacture.

Quality is Key

Taguchi was all about quality. A quality product should be cost-efficient and serve its full purpose for the consumer. A person should be able to pick up a hair dryer after a shower and dry their hair quickly and easily. In this example, a quality result consists of dry hair within a convenient time frame.

In manufacturing, there are two important aspects to ‘quality’ that we need to consider:

- Specification quality: how it compares, in terms of features and performance, to other similar products in the marketplace.

- Conformance quality: how closely the product aligns to specifications and guidelines set before production begins. You’ve probably seen QC Passed on the bottom of various products. Quality Control has confirmed that the product in question has met or exceeded these specifications.

Taguchi’s Quality Loss Function

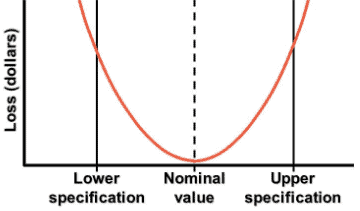

Taguchi’s Quality Loss Function was an answer to engineering tolerance thresholds being used in quality assurance tests. Traditionally, these assumed that customers would only experience dissatisfaction with a product if its performance didn’t lie within certain ranges of the ideal.

For example, take an appliance manufacturer that produces a hair dryer. The hair dryer ideally outputs 130°F of heat on each setting, with more or less air blowing through depending on the setting. The manufacturer has an output tolerance of 10%. According to tolerance-based thought, customers will only feel dissatisfied if the heat it puts out is lower or higher than the ideal by 10%. They’ll only find it too hot at over 143°F or too cool at under 117°F. At 142°F or 118°F, the customer will be satisfied.

Taguchi didn’t agree. He thought that the difference between a product just inside tolerance levels vs. one just outside tolerance levels was often imperceptible to a consumer. However, what the consumer would often notice was the difference between the product just inside tolerance levels and the ideal product.

Essentially, Taguchi’s Quality Loss Function points out that in any deviation from the ideal, some customers will experience some level of dissatisfaction. The greater the deviation, the greater the dissatisfaction that customers are likely to feel.

Why does this matter?

Using a tolerance-based method of testing products has a few issues:

- Doesn’t track variation beyond certain parameters.

- Still allows customers to be unhappy with their products.

- Doesn’t support improvements in quality if targets are being met.

Using Taguchi’s function encourages eliminating variation to get all products closer to the ideal. That flows on to higher levels of customer satisfaction.

Taguchi’s Quality Loss Function in Action

A hairdryer manufacturer discovers an issue with one of its products. At the highest setting, there is a small chance that the heating element will get too hot and start a fire.

Its engineering department offers two possible solutions. Firstly, simply decrease the power draw at the maximum setting. This would decrease the temperature at the maximum setting from 130°F to 120°F. However, it would also mitigate the risk of causing a fire. Secondly, to substitute a smaller, safer heating element. It would provide the same 130°F output at the maximum setting but a lower temperature of 110°F at lower settings.

Tolerance threshold theory would say that the first solution is perfectly acceptable, as it lies within the ideal’s tolerance levels (10%). People won’t be dissatisfied at all.

However, Taguchi’s Quality Loss Function would say that the second option is better. Customers will notice the lower heat output at the maximum setting and be unhappy with it. However, they won’t necessarily expect as high a temperature at lower settings. Decreasing the heat that the dryer puts out at lower settings makes more sense than decreasing the heat that it puts out at the maximum setting from the user’s perspective.

For more details on Taguchi Robust Design, including loss function, see this article here.

Taguchi in America

In the 1980s, Taguchi’s philosophy entered the American mainstream. The Ford Motor Co started using his methods. In 1982 he gave seminars to Ford executives; soon afterward, he became popular among business executives. Subsequently, Ford employed him.

His methods have made his name synonymous with wise business decisions. He has written a number of books related to his business philosophy. In 1986, Japan honored him for his many business and economic contributions. Just think: it is amazing what you can accomplish when you have the mindset and determination to change the thinking of many.