What is a data collection form?

A data collection form is a way of recording approach to obtaining the data that need to perform the analysis. The Measure phase of a Six Sigma focuses on data collection. Measuring parameters must be inline with the problem definition, operator to collect the data inconsistent with the process flow map, and also needs to include the inputs and outputs.

The data should record by trained operators with a calibrated instrument, and also in a standard data collection form. Too many people rush out to collect data without creating a formalized approach indicated in the data collection plan. Thought to the kinds of techniques they will use (like sampling), the categories of data needed, how they will ensure data accuracy and validity if their measurement systems are adequate, and the necessary effort to obtain the data.

Why Use a data collection form?

Data collection is a systematic process of collecting and analyzing information to extend solutions to relevant questions and evaluate the results. Filling a data collection form forces the operator to answer those questions explicitly.

Recording data in a form also get the benefit of posterity. In the future, when six sigma teams presenting or defending the research, it will show the evidence of how the teams approached the problem. It also helps when the organizations further extend or repeat the data collection, gets an idea of how and why the data captured.

How to Create a Data Collection Form

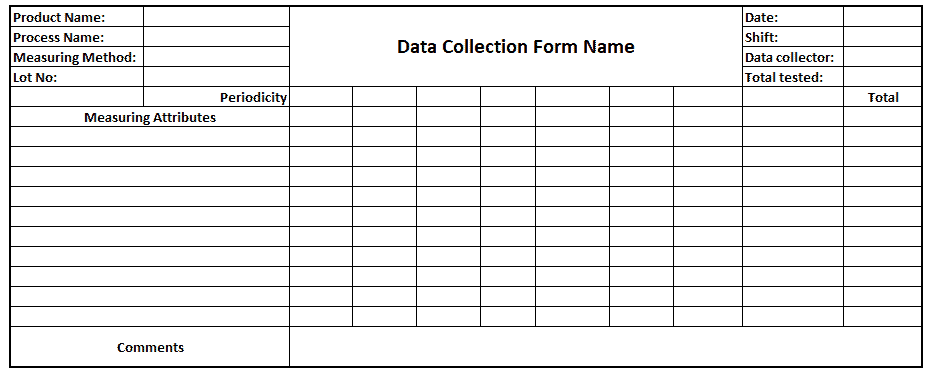

- Identify the critical data and factors of the process that needs to include in the form.

- Ask the operator or data collectors’ advice on the form design.

- Design a form such a way that to reduce the possibility of errors in recording

- Start with a descriptive title of the form.

- Provide the space to include the product (name), process stage, and also lot or batch number (where applicable). Moreover, this helps to maintain traceability throughout the product life cycle.

- Determine precision of measurement (seconds vs. minutes; microns vs. millimeters), and the same needs to indicate it on the form.

- Decide the periodicity that the operators to collect the data in the form (example: Day, week, shift, etc.).

- Provide the space for full dates (month, date, year).

- Provide a space to include the data collector name or initials and also comments columns.

- Data collection form should be self-explanatory as possible, with minimal instructions.

- Pilot test the form design and make changes as needed.

- Ask operators to practice the data collection form and applying operational definitions. Resolve any issues or differences in use.

- Make all the changes and maintain release or version number for the form template.

- Provide a professional-looking data collection form and then release it for use.

Different types of data collection forms can be created. Here’s an example:

How to Populate a Data Collection Form

Data collection includes both manual and automatic methods. Generally, manual data collection can be using printed forms on the shop floor or by data entry in the system at the time of measurement.

Automatic data collection includes electronic recorders and digital storage. Automated systems have a high initial cost than the manual system, but it has the advantage of a high accuracy rate. Moreover, the automatic system can fill the form without human interventions. The data collection frequency may be synchronous, based on predefined intervals.

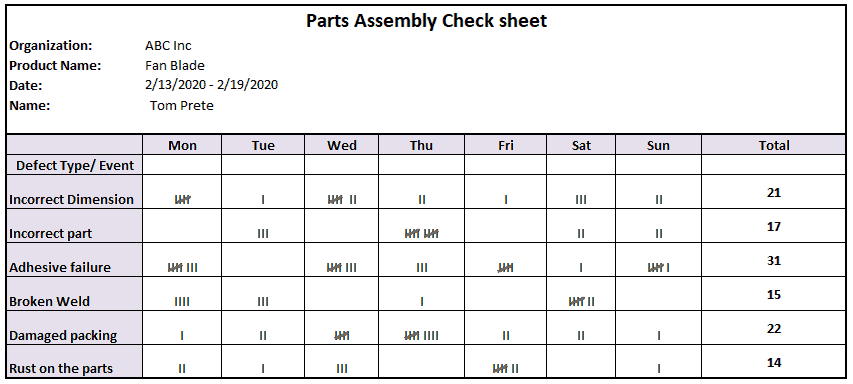

Check Sheet

Check sheets are one of the useful data collection forms to organize and collect the data. It is a structured, well-prepared form for collecting and analyzing data consisting of a list of items and some indication of how often each item occurs. By collecting data in a standard form, six sigma teams can solve problems and also can make better decisions.

- Check sheets are basically used when data is to be recorded manually by an operator, and also it is easy to use later, either for direct interpretation of the recorded information or for transcription, for example, into a system.

- Use when the recording involves counting, checking, or locating.

- To measure the distribution of a set of measurements.

There are several types of check sheets like

- Confirmation check sheets are for confirming whether all steps in a process have completed as expected.

- Process check sheets to record the frequency of observations with a range of measurement.

- Defect check sheets to record the observed frequency of defects. Measured data may be summarized by means of a check sheet also called a tally sheet.

- Stratified check sheets to record the observed frequency of defects by defect type and one other criterion. Moreover, it is easy to use, provides a choice of observations, and useful for determining frequency over time.

Benefits of check sheet:

- Collect data in a systematic and organized manner

- To facilitate classification of data

- Determine the source of the problem

- To quantify the defects by location, type and also cause

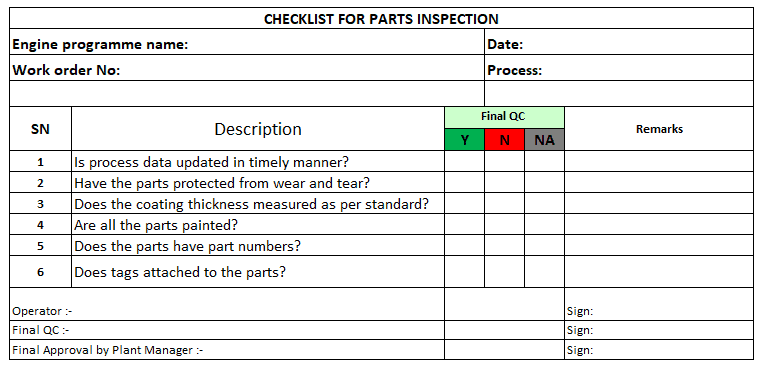

Checklist

The other type of check sheet is called a checklist. The purpose of checklists is to perform repetitive activities, to check a list of requirements, or to collect data in an orderly and systematic manner.

Furthermore, checklists help in learning a new process or sophisticated equipment. The purpose of checklists is to make systematic checks of activities or products, ensuring that the operator does not forget anything important.

How to make an efficient checklist

- Make each item on the checklist clear and concise; it should be user friendly to fill the checklist.

- Organize items by category. It will help the operator to quickly navigate the portion of the checklist that they are working on.

- Make each item actionable, so that operator can take action on each item and ensure to capture the relevant data.

- Provide comments section to ensure operators take notes, evidence, or other results to improve performance.

- Keep refining the checklist. So, it will make the checklist more effective.

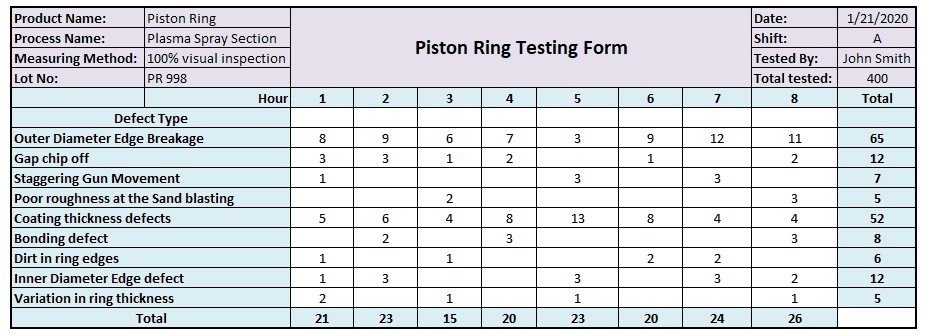

Example of Creating and Using a Data Collection Form in a Six Sigma Project.

XYZ Inc is a famous automobile engine manufacturer. The production manager reported an average of eight days delay in delivery to the customer. Six sigma team concluded that delay in shipment is basically due to high failure piston rings in the assembly. Six Sigma team created a data collection form with various defect categories and also asked the operator to 100% inspect the piston rings and report the number of defects hourly.

From the above data, it is clear that Outer Diameter Edge Breakage and Coating thickness defects were the most common defects. Now, it is easy for the six sigma team to identify the root cause and also can take appropriate corrective action.

Helpful Excel Template Downloads (Data collection form, checksheet, checklist)

When you’re ready, there are a few ways I can help:

First, join 30,000+ other Six Sigma professionals by subscribing to my email newsletter. A short read every Monday to start your work week off correctly. Always free.

—

If you’re looking to pass your Six Sigma Green Belt or Black Belt exams, I’d recommend starting with my affordable study guide:

1)→ 🟢Pass Your Six Sigma Green Belt

2)→ ⚫Pass Your Six Sigma Black Belt

You’ve spent so much effort learning Lean Six Sigma. Why leave passing your certification exam up to chance? This comprehensive study guide offers 1,000+ exam-like questions for Green Belts (2,000+ for Black Belts) with full answer walkthroughs, access to instructors, detailed study material, and more.

Comments (6)

Are there any examples that should be included here? Looks like a blank page… 🙁

Great catch, Todd. Much appreciated.

I put together a few words and a hasty example to get the point across. I’ve added a full build out of a useable resource and a case study example to my backlog of work. But I wanted to get something out there today.

Please let me know if this helps.

I am carrying out a research on the teaching of Mathematics to learners with Visual Impairments, with the aid of abacuses. I am requesting if I can adapt the ‘Data Collection Form Name’ to be used for collecting data in an quasi experimental research.

Sure, Donald. Please use standard attribution to the authors and the website.

please help me how to access free for data collection form

Hi Yohana,

Please just make an account and you will be able to access.

Best, Ted.