5S Workplace Organization is a visual system. You may have also heard it referred to as a Kaizen event.

5S derives its name from five Japanese terms beginning with the “s,” which are tools used to create a workplace suited for visual control and lean production. Collectively, the 5S’s detail how to create a workplace that is visibly organized, free of clutter, neatly arranged, and very clean. A 5S system is often a starting place for managers to apply lean operation concepts.

5S in lean Six Sigma is an approach that ensures smart workspace organization–known as ‘Good Housekeeping.’ In order to perform at a high standard, the workplace of the organization should be clean, which is guaranteed through 5S. The strategy is to engage the process teams in an effort to facilitate improvement and keep out the waste on a daily basis. 5S not only helps to reduce defects and waste but also maintains positive changes over the long term. The 5S finds its origin in the five Japanese words that capture the actions that are built into each other and that must be carried out in a particular order. These 5S words are explained in the sections below:

The 5S are:

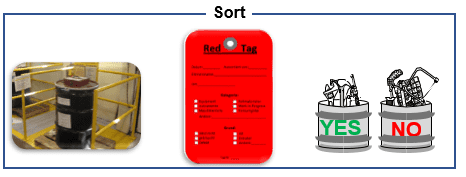

- Sort: Sorting and cleaning; remove unwanted material. Red tag all items that are not needed.

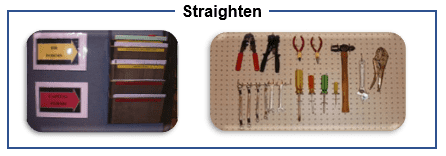

- Straighten: Organizing remaining items, adopt visual controls.

- Shine: Clean the work area as well as inspect the machinery.

- Standardize Set standards; make 5S a way of life.

- Sustain: Maintaining continued compliance.

Step1: Seiri or Sort

Sorting is the first step towards good housekeeping, and the operator must revisit all the material, equipment, machinery, tools, and other resources to determine what is needed in the workplace. The resources that are required for the process should be kept, while the others need to be returned to the right department, scrapped, recycled, or sold after seeking proper authority.

Critical items used often should be nearby, and items not needed in the near future should be stored elsewhere. You will need to sort the items to keep, items to reuse (red tag them to decide later whether or not to use them), and items to move to waste bins.

Example: Employees walk through the area and sort the office supplies, old fax machines, shredding machines, paper cutters, etc. and separate the items to use from items that should be moved to waste bins.

Step 2: Seiton or Straighten (or store)

Once the important resources are marked to be kept, and the others are marked for the trash, a unique place for each and every tool and equipment should be made. This will help the staff to know where to search for what. Also, once an item or material is stocked, the same item can be sourced without wasting time finding a place for it.

Example: Nameplates, labels, colored tags

Step 3: Seiso or Sweep (Or Shine)

A team member should clean the office or place of work daily so that the proper organization of equipment does not change. This will also foster a positive attitude and better output throughout the workplace. This, in turn, will lead to a safer work environment and a greater ability to detect defects and wastes.

Example: Cleaning the workplace and equipment to ensure it is free from oil, burrs, grease, waste, etc.

Step 4: Seiketsu or Standardize

Create a 5S system for all the worksites consistently. You should organize and standardize the worksite to help manage change as effectively as possible. Suppose a worker shifts from one worksite to another–standardizing the worksites will help the worker learn the new processes without wasting time and effort. It also improves productivity multi-fold by standardizing the workplace. Additionally, see Standard Work.

Example: Creating standards for keeping the workplace, machines, and pathways neat and clean. And also make sure to implement these standards across the organization.

Step 5: Shitsuke or Sustain

This ‘S’ means facilitating training and discipline so the entire organization follows the initial 4S. This will help to develop an improvement-oriented culture in the organization. Create a proper schedule such that everyone follows the other S’s simultaneously. Moreover, implementing the 5S’s should be the responsibility of every organization member.

Example: Implementing 5S training into daily work life, following work procedures, conducting periodic 5S audits, 5S communication across the organization, etc.

Control Methods of 5S:

One should consider some important things while implementing the strategy of 5S:

- In order to be effective, the 5S should be made visual by using colors, shadow boards, and taped-off identification lines

- Train employees on 5S

- Design a unique 5S system for every task or process

- Tie red tags to all the items you remove from the work area

- Use aisle markings, placement for forklifts, boxes, pallets, etc

- Clean each item in the workplace, including equipment, computers, printers, etc

- Use visual management tools such as color-coding, markings, and labels

- The management should participate, audit, and review the 5S system at regular times so that it remains productive and an improvement-oriented culture can be facilitated

5S Videos

Six Sigma Green Belt Certification 5S Questions:

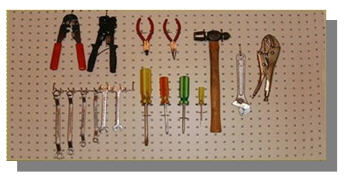

Question: A Belt has used the 5S approach of Lean to set up a control method with frequently used tools organized as shown in this graphic. The Belt has applied the ______________ principle of 5S. (Taken from IASSC sample Black Belt exam.)

a) Shining

b) Sorting

c) Straightening

d) Sustaining

Answer:

A: 5S. The phrase cluttered workstation should be the tip-off to the answer. Using 5S to standardize – for example – putting all of the tools in the right place would eliminate variation. SMED, or Single Minute Exchange of Die, is a manufacturing term for reducing the cycle time of casting parts and is not applicable. Preventive maintenance indicates taking care of tools to ensure their operating efficiency, so that’s not a great answer. Visual factory could work, but 5S is clearly the best choice.

Comments (2)

Hey Ron,

I am in New Zealand, searching google on housekeeping and up popped your video.

Brilliant,

I love it.

Thought you might like to hear how far your marketing is reaching.

Hope you are well and healthy.

I have moved from Canada to New Zealand and really enjoying life. We are not quite to the Flowserve standard but getting there in baby steps.

Keep well.

Rach

Hah! That’s awesome, Rach. Hope you are having a great time ‘down’ there!